New Plant Facility

Clean Room Facility- ISO 8 / Class 100,000

New Clean Room Facility – ISO 8 / Class 100,000

We are proud to announce the launch of our state-of-the-art Clean Room Facility, designed to meet the growing demands of precision, hygiene,

and quality control across specialized manufacturing and assembly processes.

Certified to ISO 14644-1 Class 8 / Class 100,000 standards, our new clean room facility is a major enhancement to our infrastructure,

enabling us to deliver superior performance in contamination-controlled environments. This facility is ideal for industries such as medical devices,

electronics, pharmaceuticals, optics, and precision engineering, where particulate control is critical.

Key Features:

1.ISO 8 / Class 100,000 Certified: Maintains less than 100,000 particles (≥0.5µm) per cubic foot of air.

2.HEPA Filtration System: High-efficiency particulate air filters ensure consistently clean air circulation.

3.Controlled Environment: Temperature, humidity, and pressure strictly monitored for optimal conditions.

4.Gowning & Airlock Areas: Designed to prevent cross-contamination between clean and non-clean zones.

5.Compliance Ready: Supports GMP and regulatory requirements for clean manufacturing.

This clean room facility ensures higher product reliability, reduced contamination risks, and improved process control,

helping us meet the strictest quality and safety standards. It also reflects our continued investment in innovation and our commitment to delivering excellence to our clients and partners.

With this enhancement, we are better equipped to handle complex and sensitive assemblies, setting a new benchmark for performance and quality

New Unit-Plant-4

“ We are excited to announce the official start of our new manufacturing plant, a significant milestone in our journey of growth,

innovation, and commitment to excellence. This new facility marks a major expansion of our operational capabilities and reinforces our vision

to serve our customers with enhanced efficiency and capacity with an integrate Clean Room Facility- ISO 8 / Class 100,000.

Located in U-turn Industrial Hub, Chakan, Pune. New plant is equipped with cutting-edge technologies, streamlined production systems, and sustainable

practices. With a strong focus on automation, quality, and environmental responsibility, this facility is designed to meet both current demand and

future growth.

Key Highlights of the New Facility:

1.Expanded Production Capacity dedicated for new products to meet rising market demand

2.Advanced Infrastructure with industry-leading machinery and systems.

3.Energy-Efficient and Environmentally Compliant Design.

4.Optimized Workflow for improved productivity and reduced lead times.

5.Dedicated R&D and Quality Control Units to drive innovation and excellence with an innovation centre.

A Step Forward in Our Growth Journey. “

SERVICES

Facilities & Equipment At OCI

Otter Controls India is a Indo British Joint Venture Initiative towards bringing High Quality Engineering Products and Services to various Automotive & Non-Automotive Customers in India and Abroad.

Otter Group is committed for developing and challenging the business to improve at all levels using proven manufacturing techniques.Otter Controls India has set up a lean manufacturing facility.

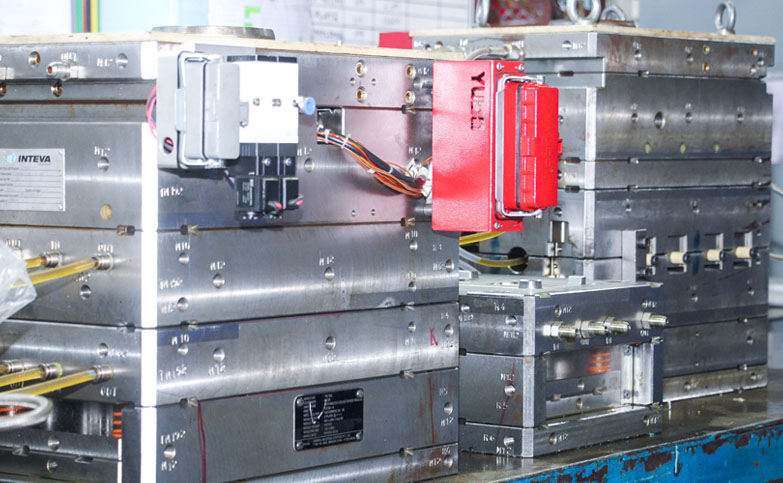

Injection Moulding operations

Vertical Molding machines –

1.TAAI make (100 T with rotary table)

2.CHNAK make 4 nos.(55 T with rotary table) and 1 nos. (100T with rotary table) (Can process and undertake metal Insert as well as Over Moulding operations)

3.All-Plast make 4 nos.(125T with rotary table), Can process, and undertake metal Insert as well as Over Moulding operations

Horizontal Moulding machine –

1.25 T Arburg

2.100 T Arburg All-rounder

3.150 T Arburg All-rounder

4.200 T Arburg All-rounder

5.250 T Arburg All-rounder (Under Procurement)

Assembly

1.Fully automatic & high precision wire cutting, stripping and crimping machine - Komax Gamma 253 Type, (Swiss made) & High Precision Crimping applicators from Mecal Italy.

2.High Quality I DC Termination Machine, Stocko (Germany) Model- WT 255.4.0.

3.High Precision FC0750 leak tester Furness Controls, UK make & ATEQ France make F520 Leak tester.

4.Miyachi Japan made excellent quality resistance welding machines

5.For 2 component silicon dispensing we have high quality silicon metering and mixing machines

6.Continuity & Configuration check testers for wire harnesses>

7.Semi-automatic heat staking machine with indexing table

8.Semi-automatic connectors assembly machines-Contacts pressing, Bearing pressing, EMC PCB pressing etc.

9.EOL testing automations for connectors- Leakage testing, Continuity testing, Impedance testing, Force checking, Height measurements, Camera checking, Laser marking & sorting etc.

10.OCI has introduced a new assembly process of Coil Winding, Robotic Soldering, Heat Stacking and Liquid Silicon rubber Injection Molding

BOBIN ASSEMBLY

AUTOMATIC SOLDERING

Machine Shop

Metal Stamping –

SEW make HSNX 45 Ton high speed stamping machine with automatic straightener & feeder.

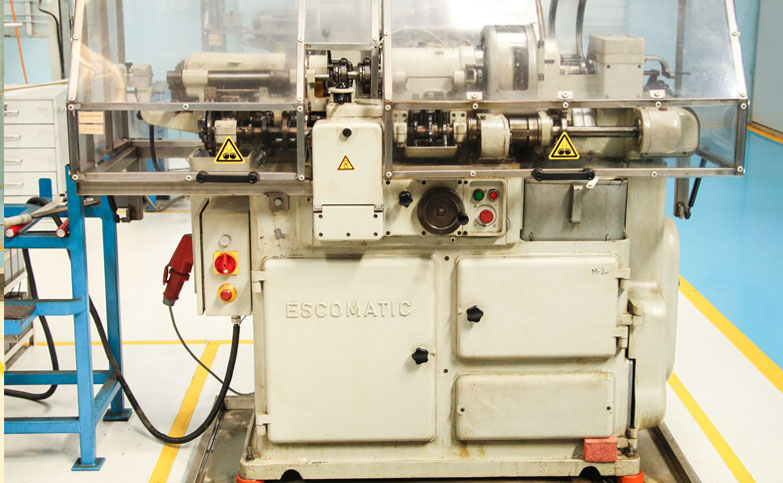

Special Pin Manufacturing –

Escomatic Switzerland made D6R automats .

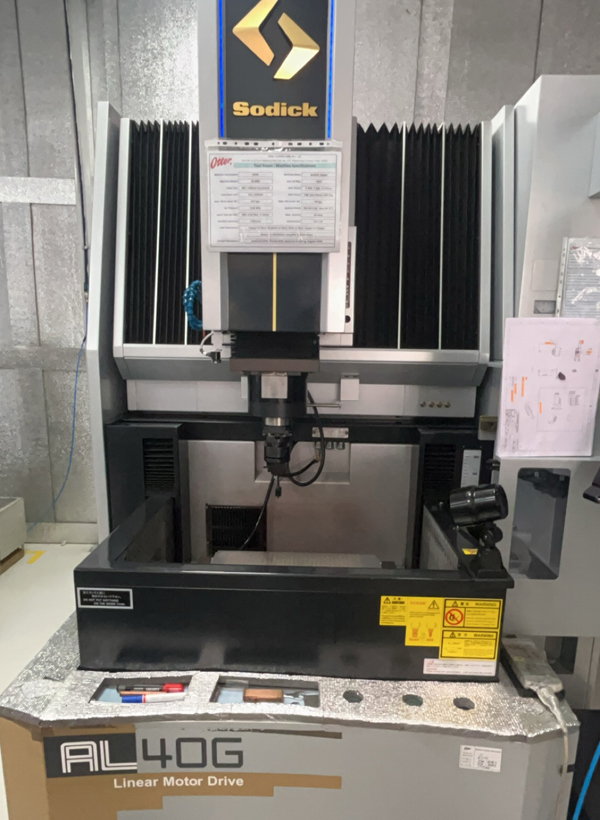

Commercial Toolroom

1.Dahanukar Make Surface grinding machine, 2800 RPM, Bed size- 600mm X 300mm

2.Mechmatrix make M1TR machine, 800mm X 400mm X 400mm travel

3.Samrat make belt drive lathe machine, SD250

4.Siddhapura SER-40 Radial Drill machine, Max drill size 40mm

5.OCI has expanded the existing tool room into an Advanced and Fully Equipped Tool Room with machines like

Wire-cut, EDM (SODICK), and VMC (MAKINO) in the year 2023.

Manufacturing

Otter controls India is a ISO 9001 & IATF 16949 certified company & follows quality management systems & procedures.

Otter controls India has successfully passed VDA 6.3 audit norms by one of its German customer.

Otter controls India is exporting its products to Germany, France, Italy, Slovenia, England.etc